I've seen it happen more times than I can count: a seller loses tens of thousands of dollars in sales during Q4 peak season because their FBA shipment got sidelined or rejected by an Amazon Fulfillment Center (FC). In one instance, the culprit was mixed (similar) ASINs with the same barcode applied to all of them. It took over two weeks to resolve—two weeks during which that inventory sat unavailable while competitors captured those sales.

This wasn't an isolated incident. During my 10 years in Amazon fulfillment operations, I witnessed countless FBA shipments get rejected or delayed for reasons that were entirely preventable. The frustrating part? Most sellers never understand why it happened or how Amazon's fulfillment centers actually process their inventory.

In this guide, I'm going to pull back the curtain and show you exactly what triggers rejections and delays at the FC - and more importantly, what you can do to avoid them.

The Hidden Cost of "Sidelined" Shipments

Before we dive into the specific issues, there's something critical you need to understand: your shipment doesn't have to be formally "rejected" to cost you money.

Amazon FCs are measured relentlessly on efficiency metrics. One of the most important is labor efficiency - essentially, how many units flow through the building versus the labor cost to process them. Everything in an FC is optimized for the "happy path": shipments that can be received, stowed, and made available for sale with minimal friction.

When your shipment has any issue - even a minor one that can't be resolved in minutes - it is likely to get sidelined. It goes into a secondary processing queue. These secondary processes are more labor-intensive, and therefore, have a higher likelihood of getting deprioritized. This means your inventory can sit there for days, sometimes weeks, especially during peak season.

There are some delays that happen naturally in the process such as FCs prioritizing hot items, out-of-stock items or easier freight to process. These may be outside of your control as an FBA seller. But the issues I'm about to cover? These are entirely within your control.

The 8 Most Common Reasons Shipments Get Rejected or Delayed

Based on what I observed across years of Amazon operations, here are the issues that cause the most problems.

1. Labeling Errors

This is the single most common issue, and it comes in several flavors:

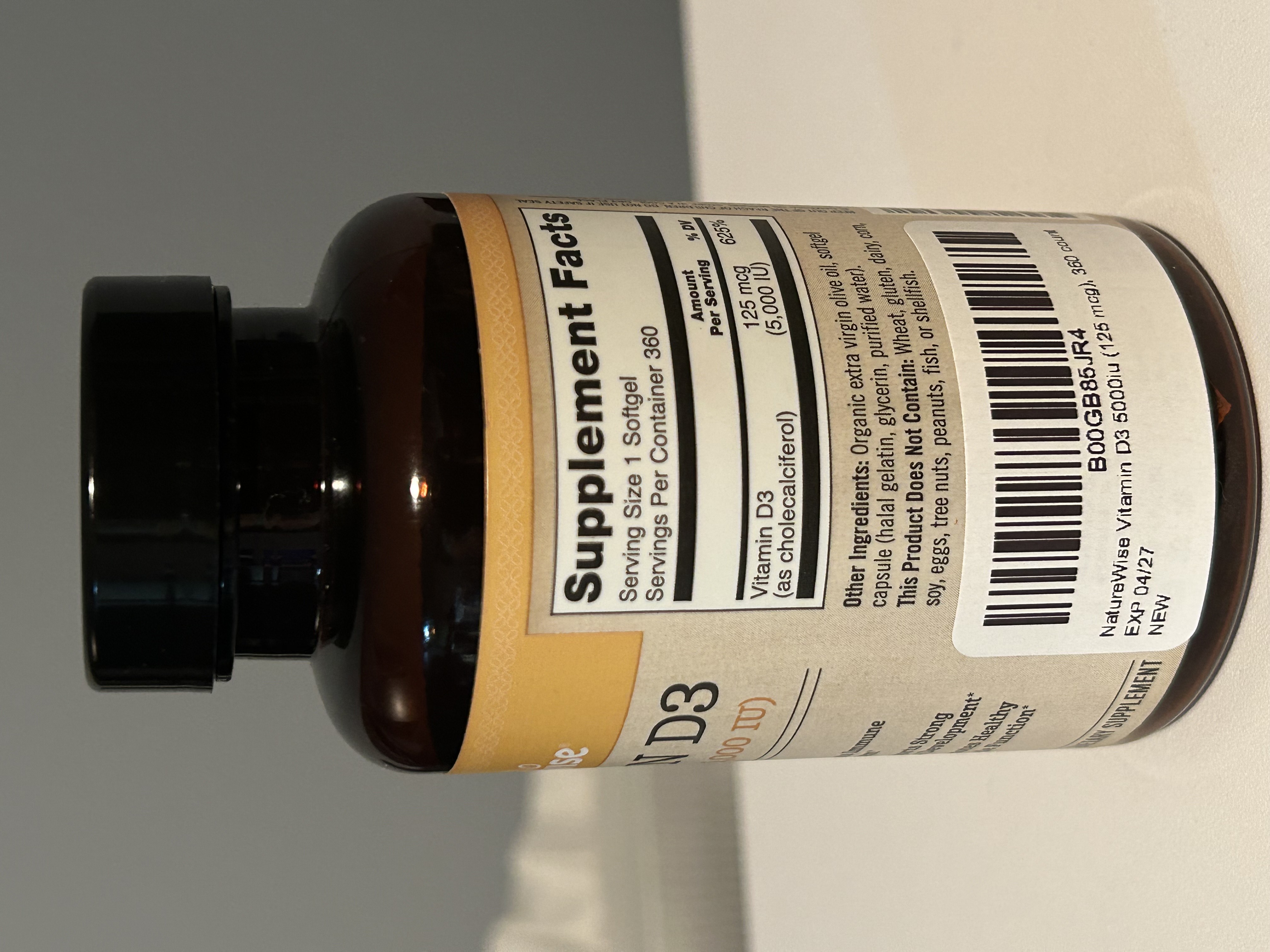

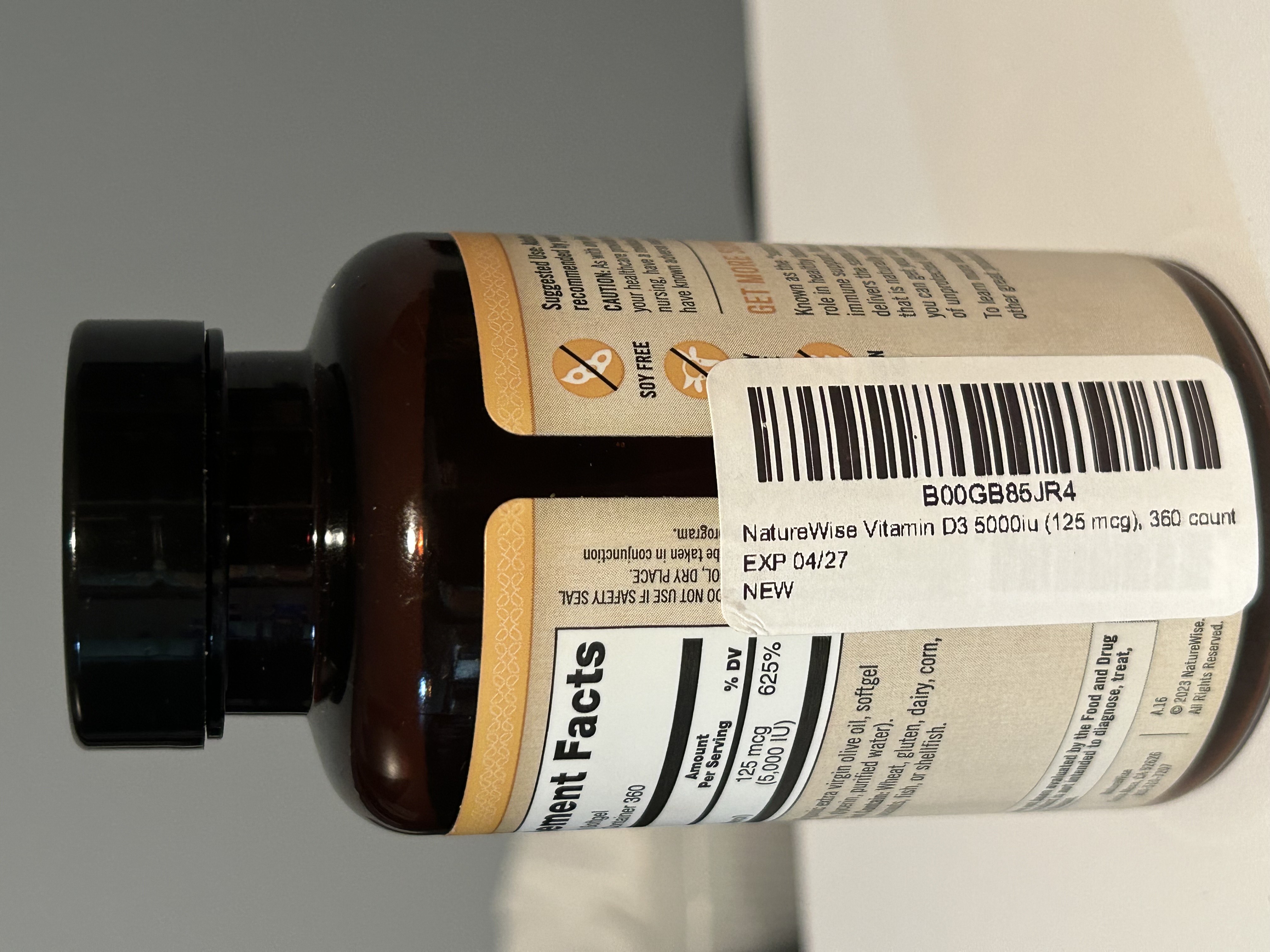

- Unscannable barcodes top the list. This includes poorly printed or faded barcodes, labels applied with folds or wrinkles, barcodes hidden under prep materials (like inside a poly bag instead of on the outside), and barcodes placed on curved surfaces — like wrapping a label around a bottle instead of applying it flat on a vertical surface.

- Missing FNSKU labels is another major culprit. If your product requires an FNSKU label (which most do for commingled inventory avoidance), using the manufacturer's UPC or EAN instead will cause problems.

- Finally, there's the issue of barcodes linked to the wrong product—or not linked at all. Similarly, having two or more scannable barcodes visible on the product creates confusion for the receiving associate.

2. Incorrect Prep for Item or Category

Amazon has specific prep requirements that vary by product type, and failing to follow them triggers immediate issues:

- Sets not properly secured: Multi-packs or bundles that aren't wrapped together or are loosely wrapped

- Fragile items with insufficient protection: Bubble wrap isn't optional for glass, ceramics, or other breakables

- Exposed sharp objects: Anything with edges or points needs proper wrapping to ensure associates' safety

- Non-concealed adult items: These must be in completely opaque packaging

- Improperly sealed liquids: Any liquid, gel, or cream needs to be double sealed to prevent leaks or spills

- Missing warning labels: "Sold as set," "Fragile," "Heavy" labels not applied on the product/box when required

3. Mixed ASINs sent with Identical Labels

This one is particularly problematic because it may or may not be caught during receiving. Sometimes, it surfaces later in the workflow—at stow, pick, or pack—and when it does, it can result in your entire shipment being placed into problem solve, making all of it unsellable until resolved.

The most common scenarios include:

- Color variants with the same label - this happens across virtually every category

- Size variants - especially common with apparel and shoes

- Configuration variants - especially common with electronics where the products look the same on the outside like laptops, phones, memory cards etc.

4. Damaged on Arrival

Sometimes the damage happens before your shipment even reaches the FC. Common causes include:

- Incorrect or insufficient packaging in master cartons

- Not enough dunnage (packing material) to prevent shifting

- Using boxes that are too large for the contents

- Damaged pallet corners (for pallet shipments)

- Products not properly sealed

- Sending used items labeled as "New"

5. Packaging Guidelines Violations

Amazon's packaging requirements exist for a reason—their systems are designed around specific parameters:

- Oversized boxes: Any side exceeding 25 inches

- Overweight boxes: Anything over 50 lbs

- Failed drop test: Packaging must survive a 3-foot drop

- Box content label issues: Missing, unscannable, or misapplied labels

- Quantity mismatches: Physical boxes don't match virtual shipment information, either missing boxes or incorrect quantities packed in boxes

- "Switcheroos": Box content labels applied to the wrong boxes (Box A's label on Box B and vice versa)

6. Expiration Date Problems

For products that require expiration dates, three issues commonly arise:

- Missing expiration dates on ASINs that require them

- Products that are already expired

- Shelf life that's too short (Amazon has minimum remaining shelf life requirements)

7. Carrier Related Issues

This primarily affects sellers using their own carriers rather than Amazon-partnered carriers:

- No delivery appointment: Carriers must request an appointment through the Carrier Appointment Request Portal (CARP) before delivering. Small parcel carriers like UPS typically have standing appointments, but LTL and truckload carriers need to request and be confirmed for each appointment before they can deliver. Failure to do this results in the carrier being turned away at the yard gate.

- Missed appointments: If your carrier misses the delivery window, they're refused and must reschedule—causing delays

- Unsafe loads: Pallets not stacked properly or posing injury risks to associates will be refused

- Lost or misdelivered shipments: Carriers sometimes deliver to the wrong FC entirely

8. Sent to Wrong Fulfillment Center

Amazon's shipment workflows specify which FC should receive your inventory. Sending to the wrong location causes problems:

- Non-sortable to sortable FC: This is the most problematic. Sortable FCs handle smaller, lighter items and have no equipment to handle oversized products. These shipments are typically rejected outright and must be retrieved or transferred at your expense.

- Wrong FC in general: Your inventory ends up in a non-optimal geographic location, or you're charged to have it transferred to the correct facility.

What Triggers Extra Scrutiny

Here's something most sellers don't know: Amazon uses sophisticated, self-learning algorithms to flag potentially problematic shipments. If your products or your seller account gets flagged, your shipments go through either a slower receiving process or get sidelined immediately for inspection before being made available for sale.

What triggers this extra scrutiny?

- Products with recent issues: If similar items (including color, size, or configuration variants) have had problems recently, expect closer inspection

- Seller history: If you have a track record of rejections or compliance issues, your shipments will be scrutinized more heavily

The implication is clear: every mistake you make today can affect how your future shipments are processed.

The Bottom Line: Why Compliance Matters

Understanding how Amazon FCs operate changes how you think about prep and shipping compliance. It's not about following arbitrary rules—it's about ensuring your inventory follows the "happy path" through the fulfillment center.

Every shipment that gets sidelined represents:

- Lost sales while inventory sits unavailable

- Potential fees and charges

- Damage to your seller account's reputation with Amazon's algorithms

- Stress and time spent resolving issues instead of growing your business

The good news? These issues are preventable. With proper prep, accurate labeling, and attention to Amazon's requirements, you can ensure your shipments flow smoothly through receiving and get available for sale as quickly as possible.

That's exactly why we built PrepMeisters—to bring the process discipline and compliance knowledge from inside Amazon operations to sellers who want to avoid these costly mistakes. When you've seen thousands of shipments get rejected for preventable reasons, you learn exactly what it takes to get it right the first time.

Ready to Get Started?

Let PrepMeisters handle your Amazon FBA prep with the expertise that comes from a decade inside Amazon. 100% compliant prep, every time.

Get a Free Quote